Materials management and storage

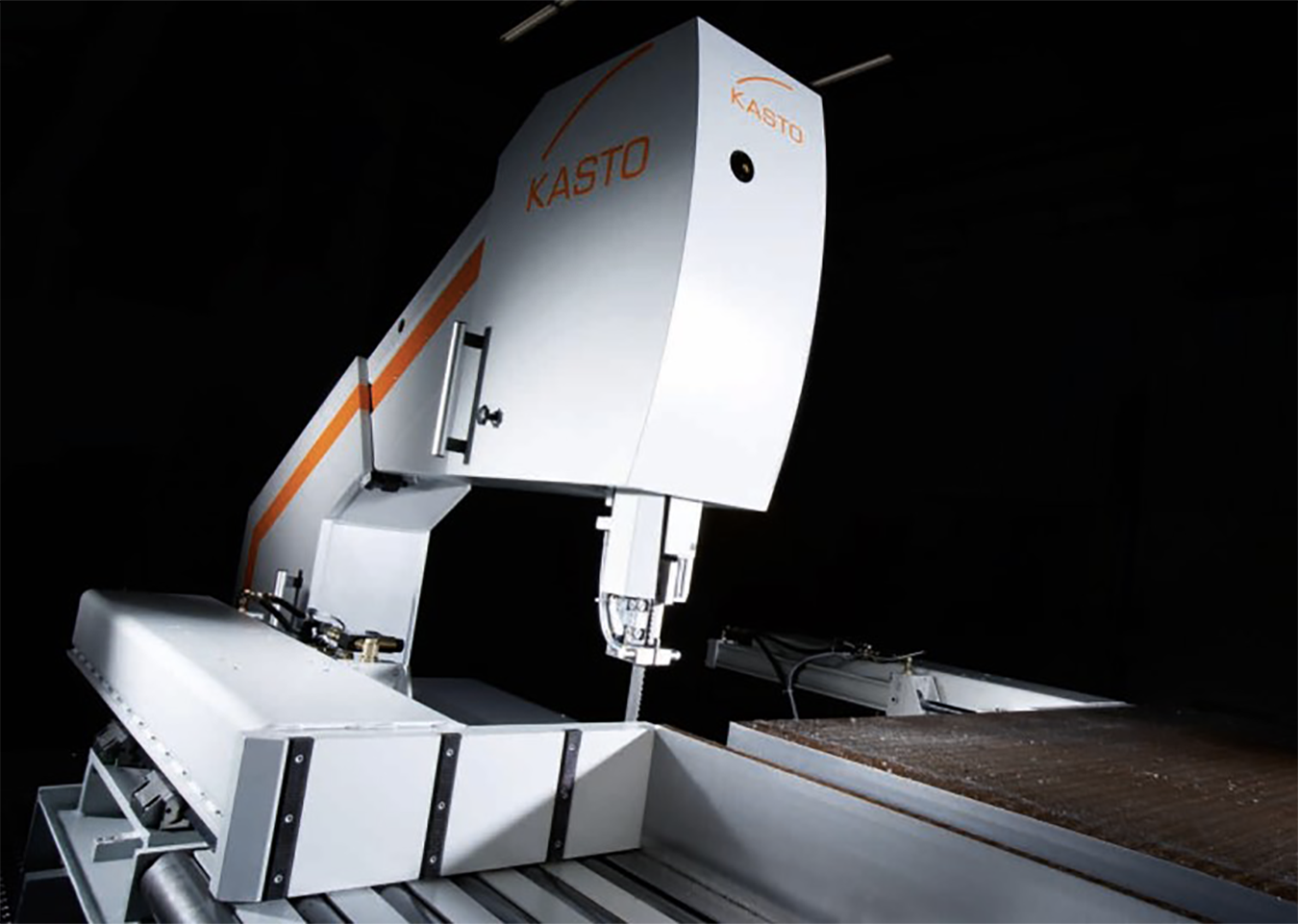

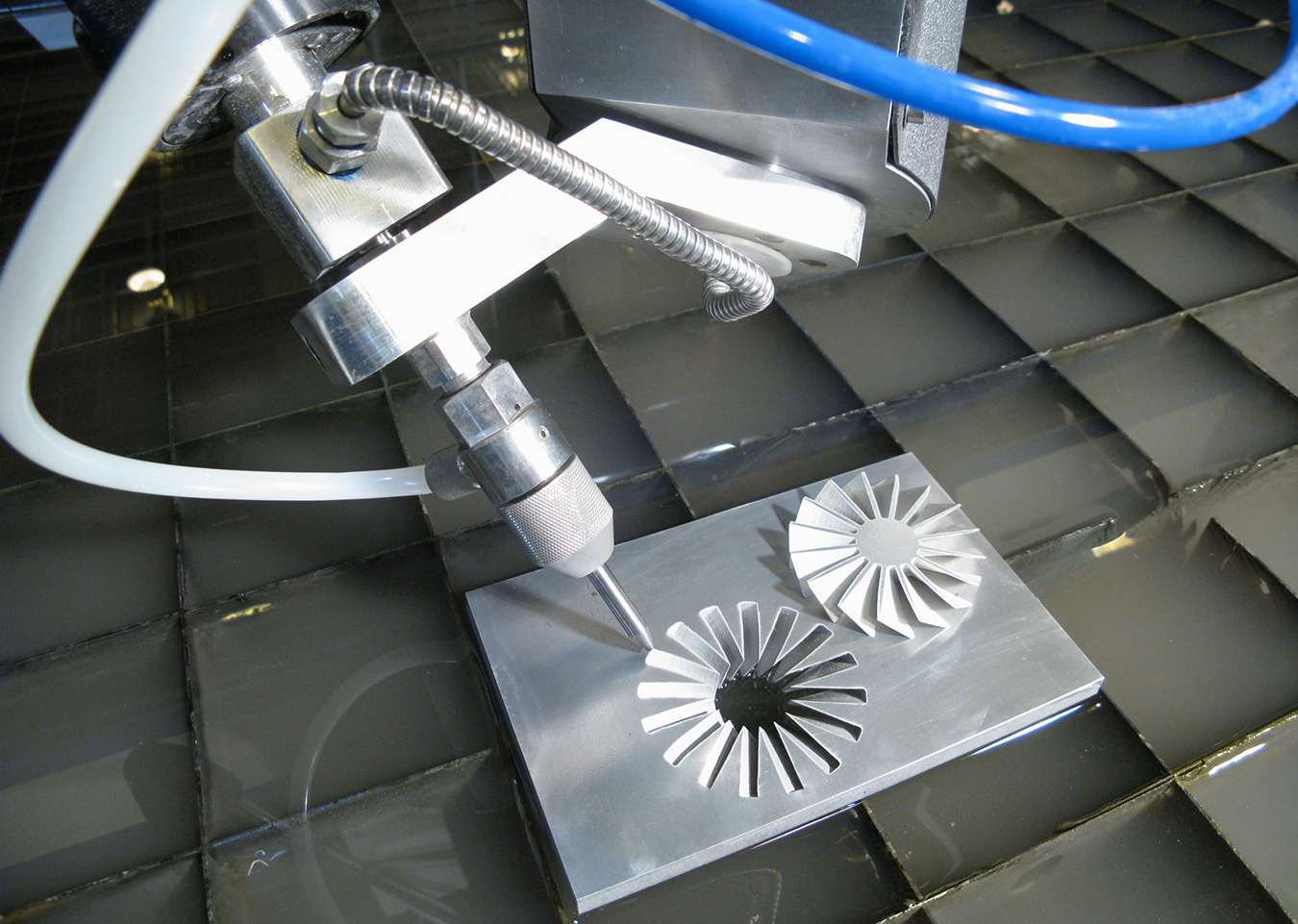

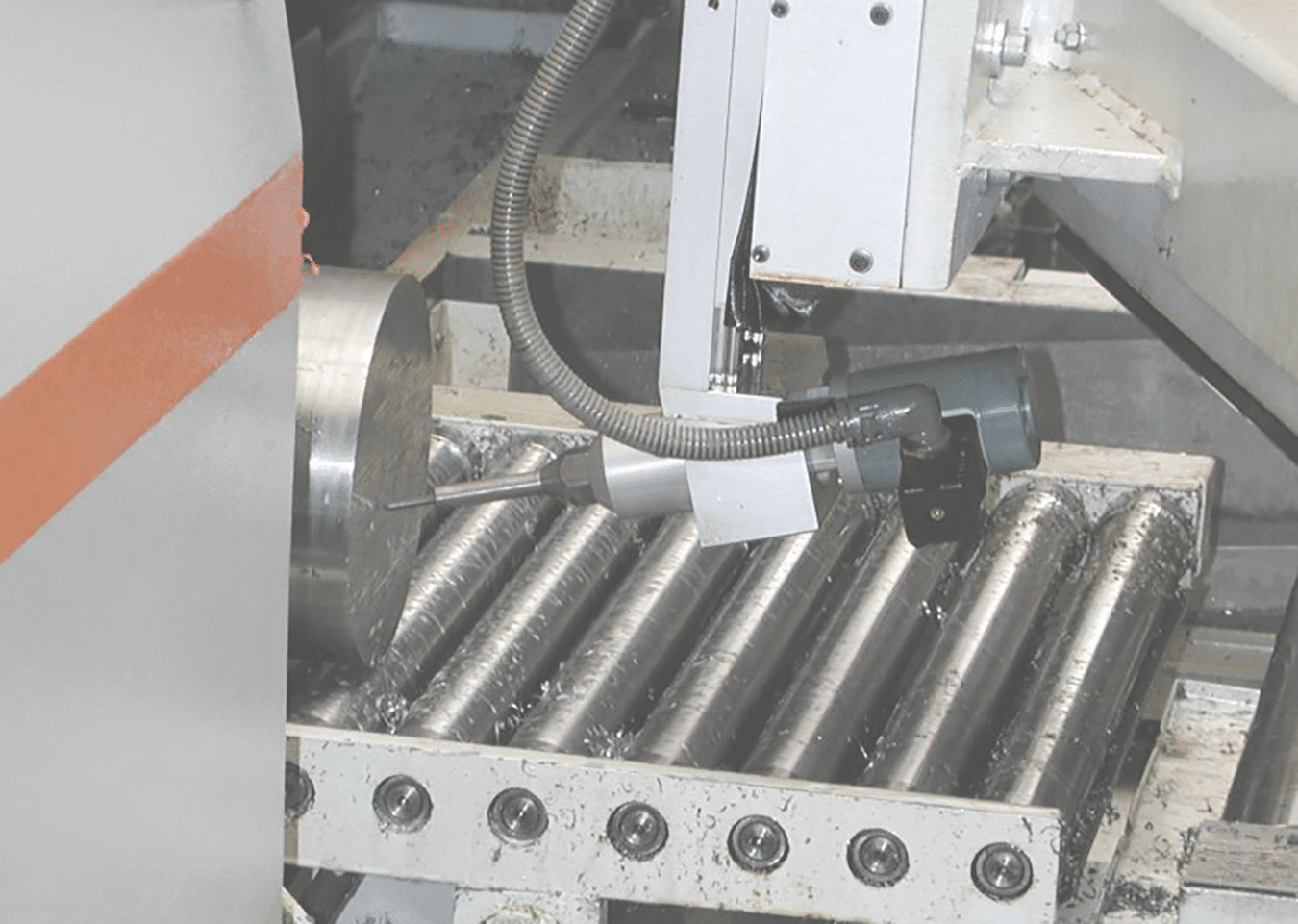

In order to control production costs and optimize processes throughout the supply chain, NEXTEAM has invested in a processing plant for raw materials specific to the aerospace industry (stainless steel, titanium, inconel, lithium), equipped with the latest waterjet cutting equipment, manual and automatic saws.

Thanks to these modern, high-performance production facilities, the Group manufactures semi-finished products in Marmande and Launaguet for its various production sites (blocks, blanks, extrusions, forgings), and provides raw material storage, cutting and logistics services for its customers in a dedicated 2,500 m2 building.

NEXTEAM’s 5-axis nesting and cutting of blanks, as well as the speed with which they can be processed, are real assets for the company and, with an average of 600 tons of titanium processed per year, a guarantee of the best possible service for customers.