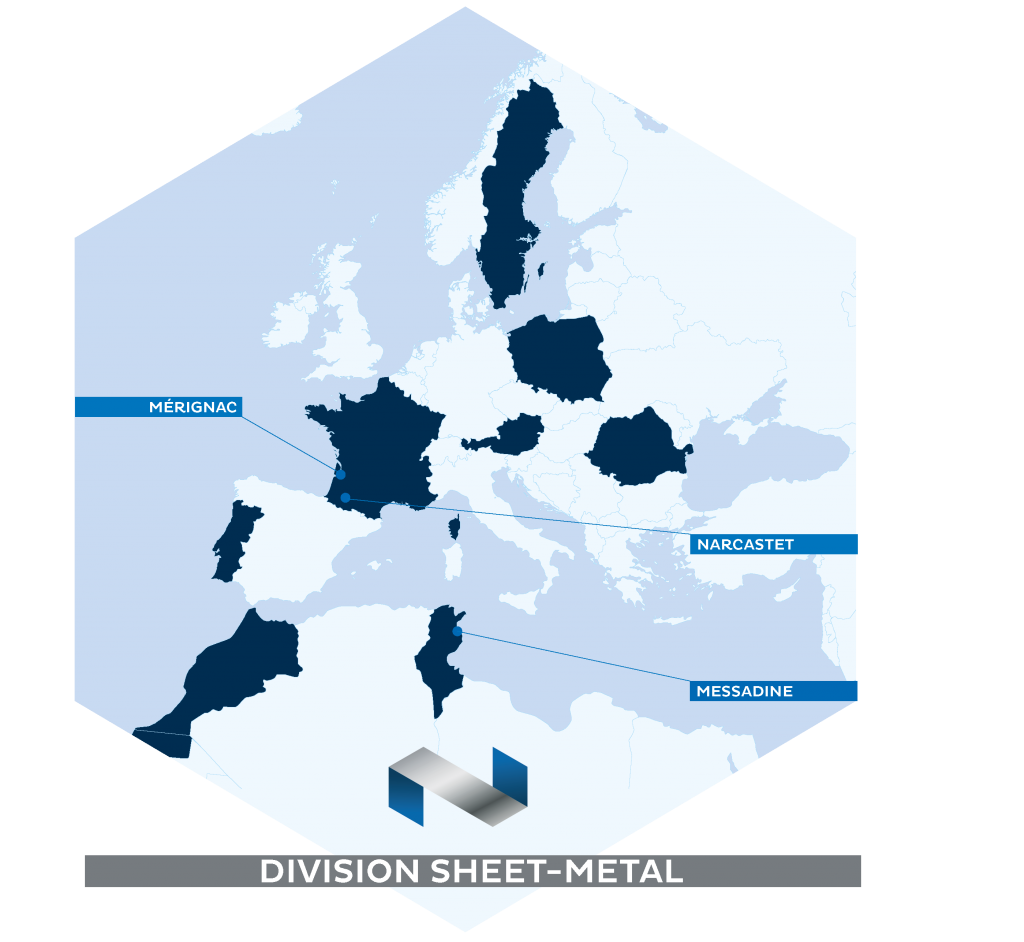

Sheet-Metal (SHEET-METAL DIVISION)

Mechanical welding activities are concentrated within the “SHEET-METAL” division which comprises 3 factories. This division brings together the activities of design, industrialization, manufacture and repair of complex mechanical sub-assemblies using a wide variety of trades: fine sheet metal work, mechanical welding, stamping, punching, bending, boilermaking, piping, electroerosion, laser welding, thermal treatment…

Precision mechanical welding ON alloys

Thanks to the great diversity of trades internalized in its workshops, the SHEET-METAL division is ideally positioned to carry out projects for the production of complex mechanically welded parts.

The metals and alloys shaped are aluminium, stainless steels, super-alloys, inconel, titanium, copper, brass, Mumetal, cobalt, tantalum… The technologies implemented include engineering and industrialization, cutting, boilermaking, stamping, bending, heat treatment, welding (TIG, Laser, spot resistance), bending, assembly and the CNDs.

Partner of major aeronautical clients, the division produces aerostructure subassemblies, from the simplest to the most complex, thanks to long-standing expertise in the use of hard metals for the production of hot parts. , in particular engine parts: engine support, nozzle, casing, combustion chamber, exchangers, etc.